Basic facts of microvalves

Everything you need to know about the "bosses" in the regulatory process. Did not find what you are looking for? Our experts will gladly assist you.

Everything you should know before

Buying microvalves

Valves are the bosses in the regulatory process

They determine the dynamics of a system and have to withstand even the highest dynamic demands. Therefore, when purchasing such key components, it is important to ensure that they are optimally adapted to the application, the particular medium and the particular environment. This is the only way to achieve a high level of safety, reliability and longevity for your applications and products. As a rule, "off the peg" solutions can not meet the massively increased demands on reliability and stability.

1. Microvalves - General

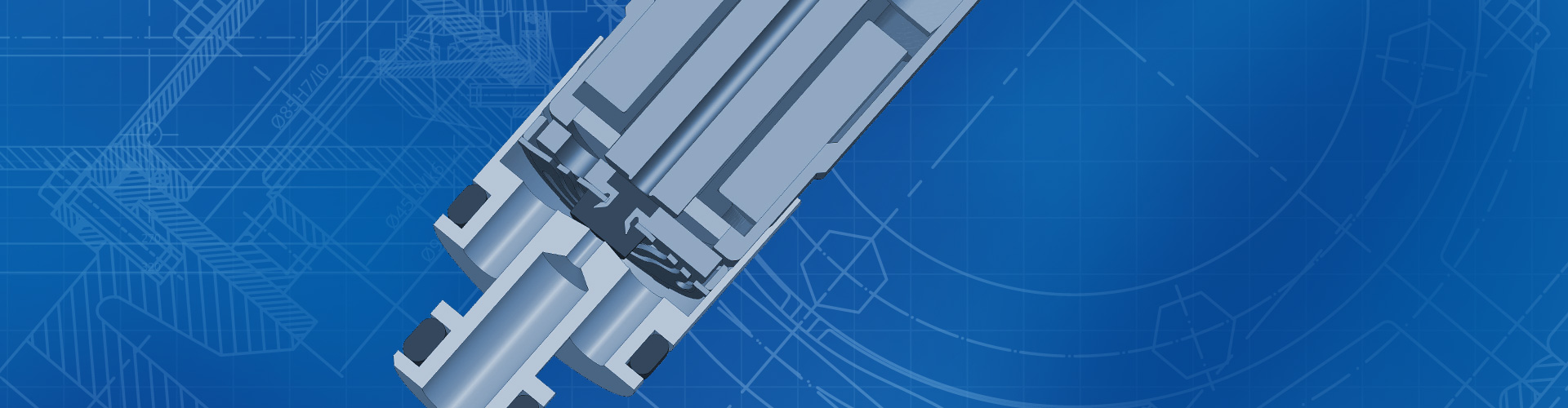

A microvalve is a particularly small component for regulating or shutting off the flow of gases or fluids. To make this possible, a closure element (e.g. a disc, a ball or a cone) is usually moved almost parallel to the flow direction of a fluid. By pressing the entire closure element onto the appropriate opening, the flow is either reduced or discontinued.

3. Microvalves - Valve types and functional principles

There are innumerable valve designs and variants and they in part fulfil completely different functions. In order to get an overview of the confusing product landscape, different segments for the categorization and differentiation of valves were defined.

3.1 Differentiation by task

Since microvalves in hydraulic or pneumatic systems are given a wide variety of tasks, a distinction can be made according to the specific tasks of the valves.

3.1.1 Switching/stop valves (on/off)

Switch valves or stop valves control the flow of a fluid by either blocking or opening the fluid channel. In case of microvalves, which withstand a high switching frequency, quasi-proportional regulation of the fluid can nevertheless be achieved by lightning-fast switching.

3.1.2 Flow control valves (proportional valves)

With flow control valves or proportional valves, the flow in the fluid channel can only be partially opened or closed, depending on the applied voltage (current). Gases or fluids thus can be precisely metered externally.

3.1.3 Directional valves

Microvalves can be differentiated by the number of connections per switching position and the number of switching positions. For example, a 2/2-way valve has two ports (A, P) and two switching positions (closed, open).

2/2-way microvalve

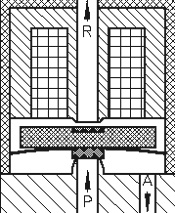

Directly controlled, NO (normally open)At rest, the leaf spring presses the seal into the lower end position. The medium can flow from P to A. After switching on the solenoid, the plunger is pulled into position. The seal is pressed against the valve seat, the valve is closed.

2/2-way microvalve

Directly controlled, NC (normally closed)At rest, the leaf spring presses the seal against the lower valve seat. The valve is closed, A can vent to R. After switching on the solenoid, the plunger is pulled into position. The seal is pressed against the upper valve seat. The valve is open and the medium can flow from P to A.

3/2-way microvalve

Directly controlled, NO (normally open)At rest, the leaf spring presses the seal against the lower valve seat. The medium can flow from P to A. After switching on the solenoid, the plunger is pulled into position. The seal is pressed against the upper valve seat. The valve is closed, A can vent to R.

3/2-way SPIDER® microvalve

Directly controlled, NC (normally closed)At rest, the leaf spring presses the disc armature with integrated sealing element against the valve seat P. The outlet A is connected to R. After switching on the solenoid, the disc armature is pulled into position and closes venting R. The connection from P to A is open. The medium flows around the armature. After switching off the solenoid, the leaf spring pushes the disc armature back to the rest position, the valve is closed.

4. Microvalves - General symbols

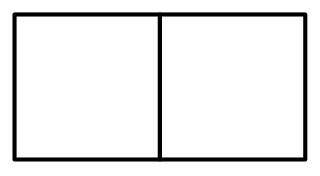

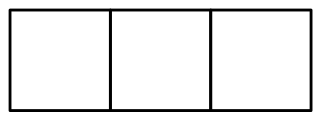

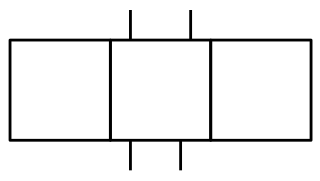

| Symbol | meaning |

|---|---|

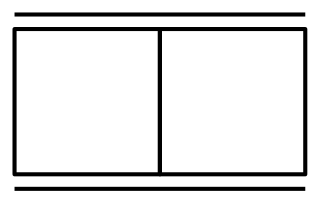

|

Directional valve with two switch positions |

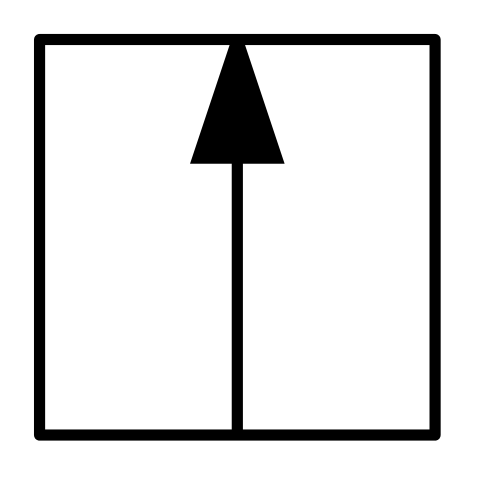

|

Directional valve with three switch positions |

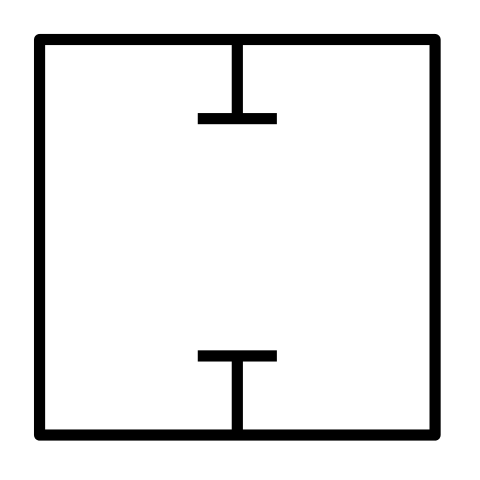

|

Directional valve with three switch positions and four connections |

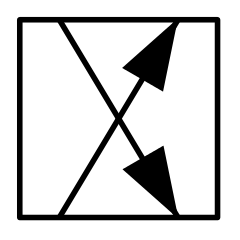

|

Directional valve with intermediate positions and two end positions, also proportional valve |

|

A flow path |

|

Two blocked connections |

|

Two flow paths |

Examples |

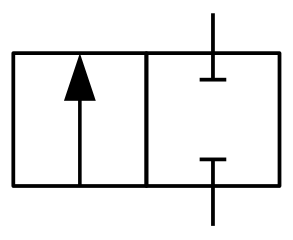

|

|

2/2 way valve |

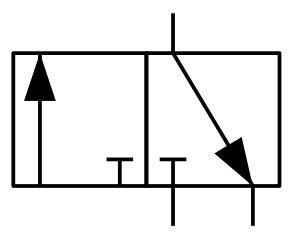

|

2/3 way valve |

2. Microvalves - Terminology (Glossary)

Before you get involved in the procurement of microvalves, you should look at the basic concepts in this context. Our compact glossary gives you a good overview.

Just click on the term you want to know more about.-

compare_arrowsNominal size [mm]The nominal size is given as nominal diameter (DN). DN is the diameter of the smallest cross-section, measured in [mm] through which the medium flows in a valve.

-

timelinePressure difference [bar]The pressure difference is the maximum pressure drop across the valve at which the function is guaranteed. AC valves have higher values than DC valves. The minimum differential pressure is the smallest pressure drop at which the valve is still working reliably.

-

placeKv value [m³/h]The flow factor Kv is a specific volumetric flow based on the medium water (temperature 5 °C to 40 °C), which flows through a valve with a certain nominal size (diameter), at a pressure drop of 1 bar.

-

powerStatic pressure [bar]The static pressure is the maximum pressure that can be applied to the connections of the valve during operation.

-

line_styleViscosity of the medium [mm²/s], [°E]The viscosity is the flow resistance of a medium due to the internal friction in the valve. The kinematic viscosity is expressed in units of mm²/s (Centistokes/cSt) and °E (°Engler).

-

av_timerSwitching timesThe switching frequency is specified as the maximum number of switching cycles per second. The switch-on time is the time between the closing of the circuit and the reaching of the stroke end position of the plunger. The switch-off time is the time between the opening of the electric circuit and the reaching of the plunger rest position.

Where can I buy custom microvalves?

Now that you have informed yourself about the facts and basic properties of microvalves, we look forward to your enquiry! We gladly discuss anything else with you in a personal conversation.